Do-it-yourself ways to make chair beds, expert recommendations

The ability to hold tools in hand is useful if you need to organize the space in a small apartment. For the optimal use of space, you can make a chair-bed with your own hands, and a step-by-step guide will help you easily cope with this task. It is better to choose a model simple, but reliable, and the texture and color of the upholstery will make it stylish.

Content

Description of work

You should start work with measurements. If there is a specific room where the chair will stand, then we can determine the width of the product, its length in assembled and unfolded form. The decision is individual, so the length can be made for the growth of a particular person. In addition, the height of the back and armrests is important.

The minimum width of the berth is 60 cm, narrower structures are inconvenient to operate.

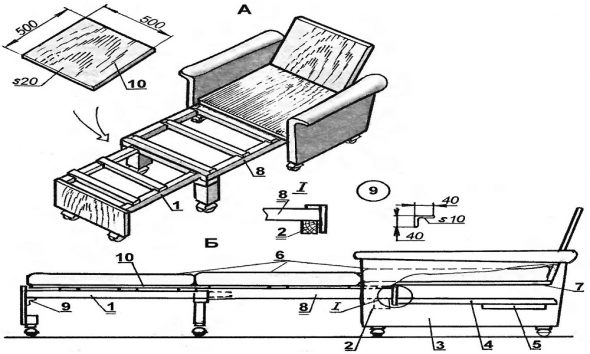

Knowing the dimensions of the chair-bed, it is easy to calculate the consumption of materials. For clarity, it is necessary to make drawings of the chair-bed with your own hands, indicate all sizes.

Materials and Tools

We determine what materials are needed to make the frame, only durable ones will do:

- 10 mm plywood for the folding part;

- Chipboard (chipboard) for sidewalls with a thickness of 18-20 mm;

- Fiberboard or hardboard on the bottom;

- bars on the frame of the folding part.

Many people prefer chipboard - inexpensive, low-toxic, easy-to-process material that will last at least 10 years. Comfort when using a chair depends on the quality of the internal filler. Sheathing the frame is better with foam.Use only solid sheets of foam, then the seat will not sag and will retain its shape and appearance for longer.

You will need a set of tools:

- stapler with staples;

- screwdriver;

- hacksaw (jigsaw);

- scissors.

For marking parts, a large metal or wooden ruler, tape measure, sharp pencil. To assemble the frame parts, you need to have screws and glue.

Body manufacture

Based on the scheme, we make the cutting of the details of the chair body and the folding part, we take the dimensions of all parts from the drawing. We cut 4 squares out of plywood. 3 pieces will go to the sleeping part, one will go to the back. Sawing can be done with a hacksaw or jigsaw.

We cut the bars:

- 6 pieces for the longitudinal part of the berth;

- 7 pieces for crossbars;

- 4 pieces for folding legs.

Mark the connection points of the parts and drill holes. We cut out the armrests from the chipboard, which we bolt to the main part of the structure. All parts are fixed with furniture screws into pre-prepared holes of a smaller diameter. Foam is glued on the sides, back, and details of the berth.

Sheathing

There are many types of materials for upholstery upholstery. This is a practical, easy-to-clean flock, and also not inferior to it in strength and color fastness of velor. Tapestry and jacquard upholstery will look good in the interior. Chenill is now popular - one of the varieties of jacquard.

We cut the fabric, taking into account the thickness of the foam rubber and the dimensions of the details of the structure. We disassemble the chair, tighten each element with a blank of fabric, and fix it with a stapler. The case is made to begin to operate a chair bed, it remains to connect details.

Mechanism installation

The operating conditions and the size of the room dictate the choice of the transformation mechanism, there are several of them:

- Eurobook;

- roll-out system;

- dolphin;

- click clack.

Roll-out mechanism is the best solution for a novice master. In operation, this mechanism is the most reliable. To arrange a berth you need to push forward two sections, and lower the back to a horizontal position. To connect parts it is worth using piano loops and bolted connections. Using such a transformation mechanism, you get a box for linen, located at the bottom of the box.

The disadvantages include the fact that in the assembled form, the model with a roll-out mechanism looks cumbersome, but its reliability and the presence of a box for linen justify the choice.

The nuances of making a frameless model

Frameless armchairs are preferred by young people. This type of furniture is practical, consistent with modern fashion. The frameless bed-chair lacks hard parts; it is a transformer assembled from pillows.

Having several frameless armchairs, you can combine them: make a sofa, move it to different ends of the room, placing it near the TV or coffee table. Joinery is not needed, for work you will need a sewing machine, scissors, a ruler, chalk.

The chair-bed can be made of foam rubber sheets with a thickness of 10 cm. We glue them in pairs using PVA construction glue. We cut the dried out layers using a ruler and a marker, we cut precisely according to the marking with scissors, we get the blanks:

- square 80x80 cm - 2 pcs;

- rectangle 30x80 cm - 1 pc;

- rectangle 20x80 cm - 2 pcs.

Parts cut to size have a thickness of 20 cm. The next step is to cut the fabric. During operation, it is important not to forget about allowances for seams, they should be at least 2 cm, where the zipper will be sewn, the allowance is more - 3 cm.

When stitching parts, use a braid for strength and durability of the seams.

Take the time and money - sew 2 types of covers. Some are rough from inexpensive mixed fabric, the second are smart from high-quality furniture fabric. Get several rectangular blanks folded in half, they are equal to the size of the blanks made of foam. In a single design, parts are assembled using zippers sewn into covers. Zippers will need 7 pieces each 80 cm long.Now you know how to make a chair-bed with your own hands, the proposed ideas can be taken as a basis, and for your apartment come up with a more original solution and implement it.

Video