Features of making DIY sofas, master classes

Typical furniture is not always suitable for a particular interior. When the standard options do not fit into the situation, you can make a sofa with your own hands - after all, any craftsman will cope with the work. To do this, you need drawings, materials, step-by-step instructions. The product, assembled independently, will last a long time, and it will also be interesting to look in the room.

Content

Preparatory stage

Work at home should begin with creating a scheme. To make the correct drawing of the sofa, you must:

- Choose a transformation mechanism.

- Decide on the dimensions of the finished product, depending on its purpose (for sleeping or relaxing), as well as the area of the room in which homemade furniture will stand.

- Choose a model that fits in shape and design.

- Prepare everything you need for work.

When choosing or independently building a drawing, it is important to take into account the characteristics of a particular material from which the home master plans to make homemade sofas. When the scheme is ready, you can proceed to the next step - the calculation and order of metal, wood (or plywood, chipboard), filler, upholstery fabric, supplies.

Upholstered furniture of a standard type consists of two blocks - a back and a seat. When unfolded, these components form a berth. A corner sofa made of plywood is a construction of three modules interconnected in the form of the letter G (less often - P). The furniture stands on four legs; in some models, rollers are used instead.

If the product is intended for rest and night sleep (for example, for a bedroom or a nursery), a design may include a niche for bedding. It is also convenient to put children's toys or old, unnecessary things in such a box. The presence of a special box makes the furniture more functional, but increases the weight of the sofa, makes it difficult to transport.

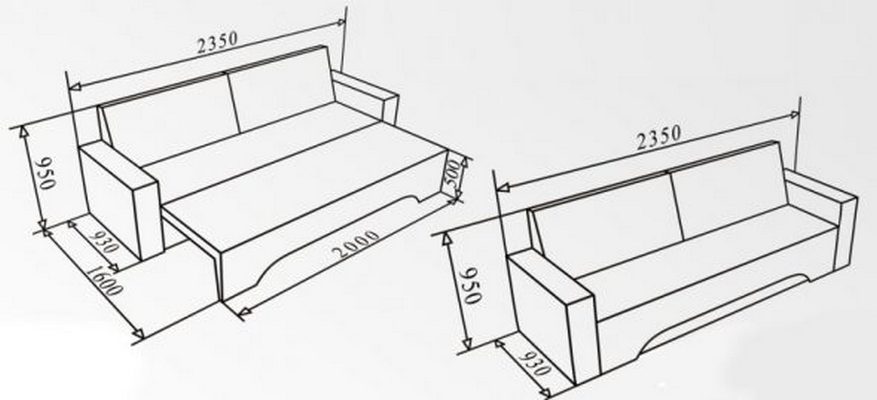

Before you study the drawings and diagrams, you need to determine the size. The standard dimensions of the product with the book mechanism are 140 x 220 cm when unfolded.TOWhen the furniture is assembled, these dimensions are reduced (100 x 220 cm).

First, the individual parts (modules) of the product are made, and then combined into a single whole. Assembling a sofa is the most crucial stage. Combining the two main elements together, the master must ensure that the seat when folded does not extend beyond the armrests. When the sofa is unfolded, the distance between the frames should not be less than 10 mm.

The backrest with seat are made of blanks. Their number is the same for any model. Need to cut:

- a rack;

- upper and lower rungs;

- side bars;

- overlays.

You will also need two crossbars for the seat - rear and front.A board of 50 mm is suitable for manufacturing. Lastly, they make blanks for the back and seat panel.

Materials and Tools

For the manufacture of the frame, wood is most often used. Less expensive options are possible - plywood or chipboard. Metal frames are the strongest, but they have one drawback - the large weight of the finished product. Experienced craftsmen take such wood species as:

- Pine;

- Birch;

- beech;

- alder.

When choosing a drawing, you should pay attention to the fact that each scheme is designed for specific materials. A drawing of a metal frame is not suitable for those who decide to make a sofa out of wood, and vice versa. For additional rigidity, experts recommend the use of a crate made of wood, plywood or chipboard. It can be made independently or replaced with industrial slats.

For upholstery, it is recommended to choose velor, tapestry or jacquard. These fabrics are resistant to dirt and easy to care for. The most popular fillers are batting, synthetic winterizer and pressed felt. They are distinguished by elasticity and high density. A synthetic winterizer is a cheap option, but it does not last long.

It is necessary to prepare in advance the tools necessary for assembling the product at home. First of all, it is a furniture stapler (for upholstery) and a screwdriver. Also, the master will need:

- ruler;

- wooden or metal square;

- stationery cutter knife;

- miter box.

It is necessary to purchase and dissolve in advance according to the instructions carpentry glue and foam rubber. Also, consumables will be required: self-tapping screws, wood screws, nails, staples. After that, you can start work.

In Soviet times, foam rubber was most often used as a filler for upholstered furniture. It does not last long and can cause an allergic reaction. When hauling old sofas at home, the foam is usually additionally compacted with synthetic winterizer.

Transformation mechanism selection

You need to choose high-quality good metal parts that can withstand heavy loads. Each mechanism has its pros and cons. They are presented in the table below.

| Title | How does it work | Advantages and disadvantages |

| Book | Two frames with fixed spring blocks are responsible for the transformation, instead of which a soft filler can be used. | The backrest easily reclines; you can place a box for storing bedding at the bottom. However, such a sofa is difficult to expand if there is not enough space in the room. |

| Tango | The principle of operation is similar to a book, but the back of a corner sofa (or a product of standard shape) can be in three positions: horizontal, vertical and intermediate. | The furniture is compact in size, when laid out on the sleeping surface there are no bumps, but the backrest cannot be leaned against the wall. |

| Eurobook | The seat rolls forward thanks to small rollers, the back is hidden in a special niche. | The mechanism lasts a long time, the sleeper occupies a large area, but the rollers can leave scratches on the linoleum. |

Most often, in home-made products, the book mechanism is used. It is easier to craft from improvised materials. If the spring blocks are made of quality raw materials, they do not wear out for a long time. A more modern modification of this model is the do-it-yourself sofas of the eurobook.

The French clamshell mechanism is very popular among fans of transformer sofas. To lay out the bed, just pull the edge of the seat and the three sections of the product will straighten. However, this option is not suitable for home-made furniture, because such a mechanism quickly fails.

If the room in which there will be a wooden sofa is spacious enough, you can use the accordion mechanism.Such a product takes up very little space when folded, but requires a lot of space for folding. When the berth is pushed forward, it rests on the moving legs. The main advantage is that you do not need to exert physical effort for folding.

Sofas accordions last a long time, but traveling legs can scratch the floor. Also, they have nowhere to build a box for bedding, and the niche is located in the rear back, which is not very convenient.

Model-specific manufacturing steps

Step-by-step instructions for making furniture for sleeping and relaxing may vary by model. Most often, home craftsmen make classic books, corners and modular products from pallets. Each option has its own design features. The instructions for assembling sofas depend on them.

Sofa book

For work, you will need a bar and boards, foam rubber as a filler and upholstery fabric. Also, a ready-made transformation mechanism is needed. Consumables require nuts, screws, furniture bolts, staples. Below is a step-by-step instruction. It is necessary:

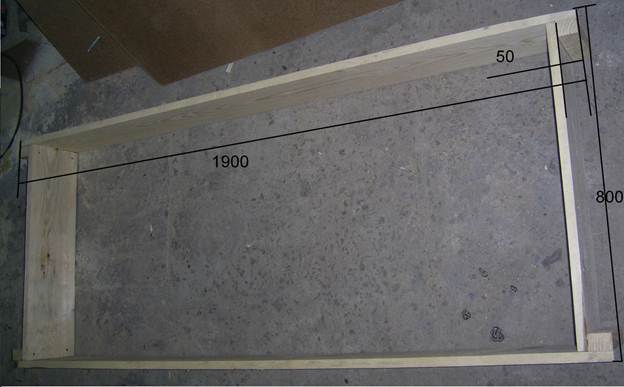

- Assemble a drawer for linen from 1900 mm boards. Strengthen the finished product with 2 rails.

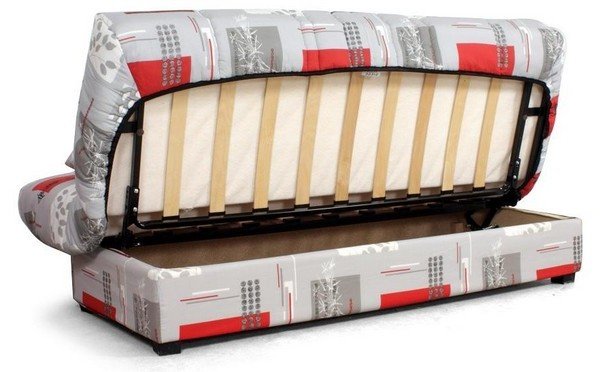

- Make two frames - for the seat and back, fasten lamellas on them to support the mattress.

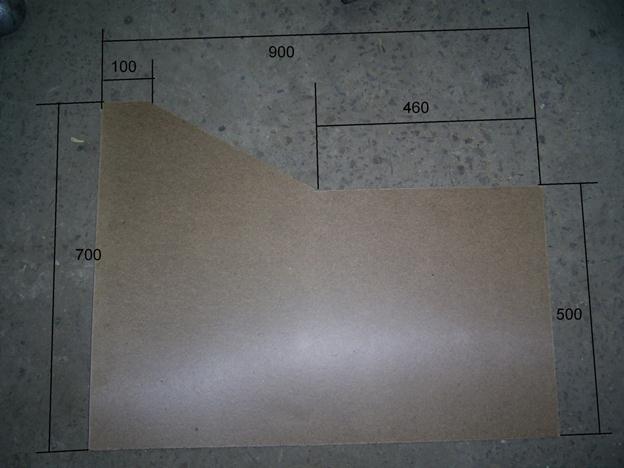

- Cut armrests from fiberboard. Use boards 55 mm wide and 1 m long.

- Make a wooden frame for the armrests and assemble the parts in one piece.

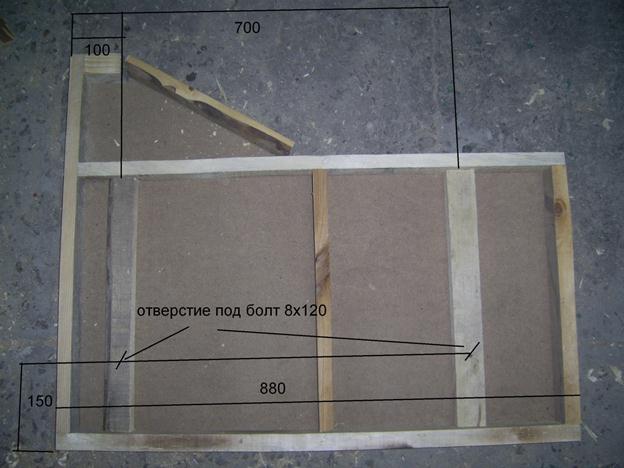

- Drill holes in the bedding drawer.

- Assemble a sofa book from the modules.

When installing the transformation mechanism, make sure that in the horizontal position the distance between the back and the seat is about 10 mm. To strengthen the structure, you can additionally apply a grid of rails. The frame is sheathed with sheets of foam. To smooth sharp corners along the edge of the product, it is recommended to glue as an edging an additional strip of the specified material. If everything is done correctly, you should get a soft roller. The sofa book is compact and comfortable, has an interesting design.

Angular

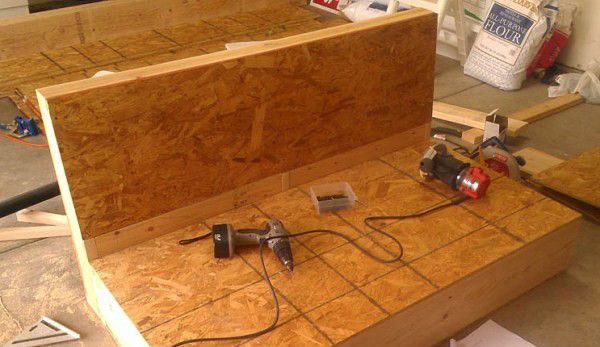

For work, you need a bar and boards. You should also pick up plywood or chipboard in advance. The first option is more durable and reliable, the second is cheaper. The minimum recommended chipboard thickness is 16 mm, it makes no sense to take material thinner. Work Stages:

- Draw a drawing. Calculate the length of both modules.

- Make a diagram in which the locations of the fasteners will be indicated.

- Assemble and fasten the rectangular frame from the boards with screws.

- Install the cross bars in the center of the lower and upper parts.

- Fill the bottom of the box with fiberboard.

- In the described way to make the second half of the product, the corner insert of a square handicap.

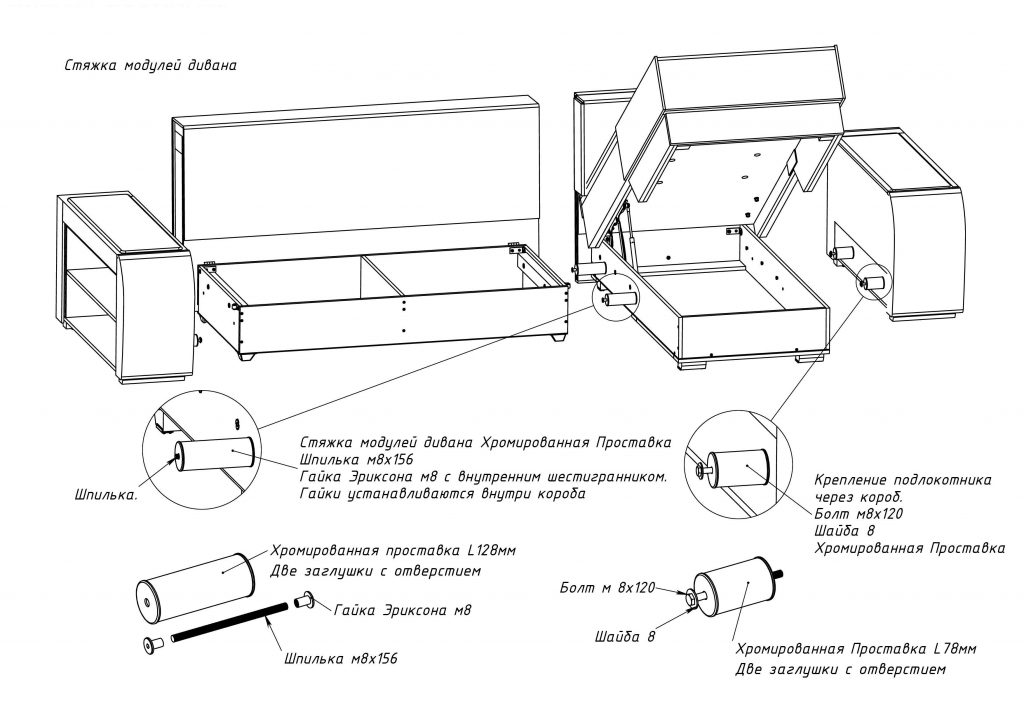

- Fold and fasten the three received elements.

- Make a backrest of 6 modules, fasten all parts to each other using a beam.

- Place the seat on the hinges attached to the backrest components.

- Fill upholstered furniture with foam rubber at least 10 cm thick.

- Sheathe the frame with upholstery.

For upholstery you will need a furniture stapler. It is recommended to start lining from the farthest corner of upholstered furniture, gradually moving to the center. Nail matter to the back is necessary from the bottom up. When this part is already processed, go to the sides. The last thing is covered with fabric seat.

From pallet

Pallets are wooden pallets. They can be found in any hardware store. Masters use pallets as modules in the manufacture of upholstered and cabinet furniture at home. To make original sofas with your own hands for a summer residence, you need one large pallet. For work it is necessary:

- Saw the pallet into 2 fragments - large (seat) and small (back).

- Screw the legs to the seat with screws.

- Lock the backrest in position. To do this, you will need wooden corners.

- Primer and varnish the furniture surface.

- Fix the plywood for the backrest on the crossbars using the hinges.

If the product will be in the country or on the balcony, it is best to sew a protective cover and decorative pillows from faux leather. This material is unpretentious in leaving. Also leatherette tolerates high humidity and has a long service life.

To make a product of standard sizes, suitable for sleep and rest, you need 6-8 pallets. Manufacturing technology will be about the same. One of the pallets needs to be disassembled on the board and used to fasten the modules to each other. Before you start sleeping on such furniture, it is advisable to lay an orthopedic mattress.

Useful Tips

To make a soft sofa, it is recommended to choose functional models with drawers and a filler of good quality. Vykatny (sliding) options with rollers and guides are very popular. They are good in that you do not need to exert physical effort for folding.

You should not save on accessories, because the life of furniture depends on the reliability of the fasteners. It is better for novice joiners and carpenters to choose clear geometric patterns. They are suitable for interiors in any style. They are also much easier to make clearly and accurately compared to furniture of complex shapes.

Thorn joints located at the ends of the boards increase the strength of the product and increase its service life. However, it is impossible to make them at home, this requires special equipment. For this reason, the novice joiner should not set himself such a task.

Experts do not advise interconnecting individual elements with nails. Instead, experienced craftsmen use screws or self-tapping screws. If nails are used, the fixtures are gradually loosened.

Recommended wood species for making a sofa at home - spruce and pine. Before work, the boards are carefully sanded - the surface of the material should be smooth, without roughness. It is not necessary to cut boards indoors, as wood dust accumulated in the air is harmful to health and can cause allergies.

For stuffing the back, you need to use thin foam rubber, for the seat - more dense. You can glue several sheets together. It is necessary to pay attention to the density of joining of soft parts with each other. A thin layer of synthetic winterizer is laid on top of the foam to protect the filler from external influences. In furniture factories, it is used to make sofas softer.

The frame must support the weight of several people. A children's sofa made of timber is calculated based on the weight of the kids (adolescents), an adult - depending on the complexion of older family members.

In order for wood products or chipboard to serve for a long time, all details must be treated with special furniture varnish (stain). If the garden sofa is intended for children to relax, the cover should not contain aggressive and allergenic chemicals. Homemade sofas have many advantages.They fit well into any space, look unusual, suitable for sleeping and relaxing. The main thing is to choose high-quality material for work and clearly present a step-by-step sequence of actions. Then making do-it-yourself upholstered furniture will become an interesting hobby.

Video