The steps of making a cabinet from furniture panels with your own hands, everything in detail

Many people prefer to create a variety of interior items with their own hands. In this case, they embody their ideas in them, and also provide a high-quality product, as they use only suitable materials during work. A good solution is a cabinet with your own hands from furniture panels, which is very simple to make, and also it is highly environmentally friendly, durable and reliable. In every apartment or house there is certainly a closet that acts as the main element for storing numerous items, clothes or shoes.

Content

Benefits

The advantages of self-creation of such a design using a furniture board include:

- you will not need to spend a large amount of money on this process;

- it is possible to realize your own unique ideas regarding obtaining an unusual cabinet;

- it may have a non-standard shape and design, but for this, before assembling a cabinet from a furniture board, it is necessary to make competent calculations;

- the resulting wardrobe will fit perfectly into the existing interior style, so it will become a real decoration of any room;

- for him, you can choose any suitable fittings, as well as make the optimal number of shelves and drawers.

Thus, the independent creation of a cabinet using furniture panels is the optimal solution for each owner of residential real estate who prefers to do a lot of housework with his own hands.

Material preparation

Do-it-yourself cabinet creation from furniture panels begins with the preparation of the necessary materials for this work. The furniture board is a special material made on the basis of natural wood, and under the press the wooden blocks are correctly glued together.

In the market furniture panels are presented in numerous forms. They differ in size, thickness and wood species used in the manufacturing process. The most popular are products made of spruce, pine, oak or birch.

The advantages of using furniture panels to create furniture include:

- environmentally friendly materials, in the composition of which there are completely no any true or even dangerous components;

- are easy to handle, so you can get designs that have an unusual and bright appearance, as well as a non-standard shape;

- the cost of the material is considered affordable for each buyer;

- it makes really attractive cabinets.

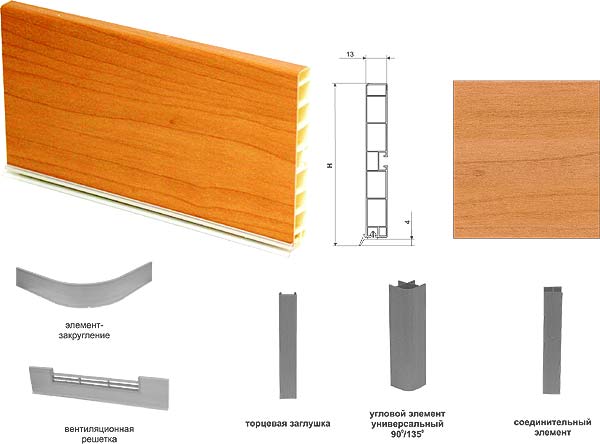

To create a cabinet from a furniture panel with your own hands, materials are prepared:

- the furniture board itself, and it is desirable that its thickness be 2 cm, and it will be used to create not only the body, but also the facade of the structure;

- plywood, with the help of which different shelves will be created, moreover, its thickness should be equal to 1.2 cm, and also often this material is used for saving to form internal partitions in the cabinet and its back wall;

- 6 mm plywood used to create drawers, if they are planned to be in the cabinet;

- furniture bar and various holders that provide an efficient and optimal arrangement of various clothes and other items in the structure;

- numerous accessories, which include handles, hinges, guides and other elements for comfortable use of the cabinet for its intended purpose.

Furniture covers are also commonly used for the lid and bottom. Previously, you can provide for the presence of a backlight in the design, for which point lights or a special LED strip are used.

Instruments

If you plan to assemble the structure yourself, then you should prepare the necessary tools for this work in advance. These include:

- varnish for wooden structures;

- self-tapping screws for reliable fastening of individual elements of the product;

- an electric drill, to which there should be different drills;

- a chisel, screwdriver, pencil and tape measure, as well as a hacksaw for working with wood;

- grinder for wood processing.

All of these tools are simple, which is why every man who does a lot of housework is usually available.

Drawing

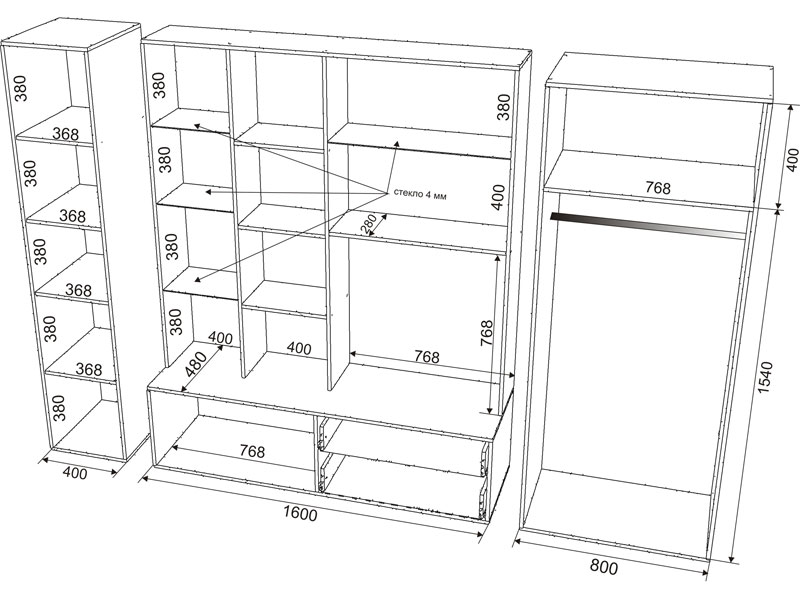

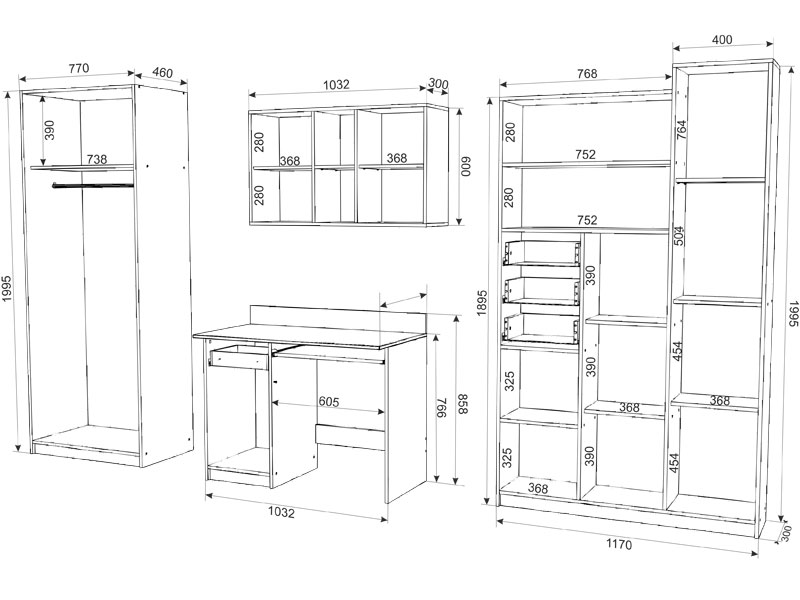

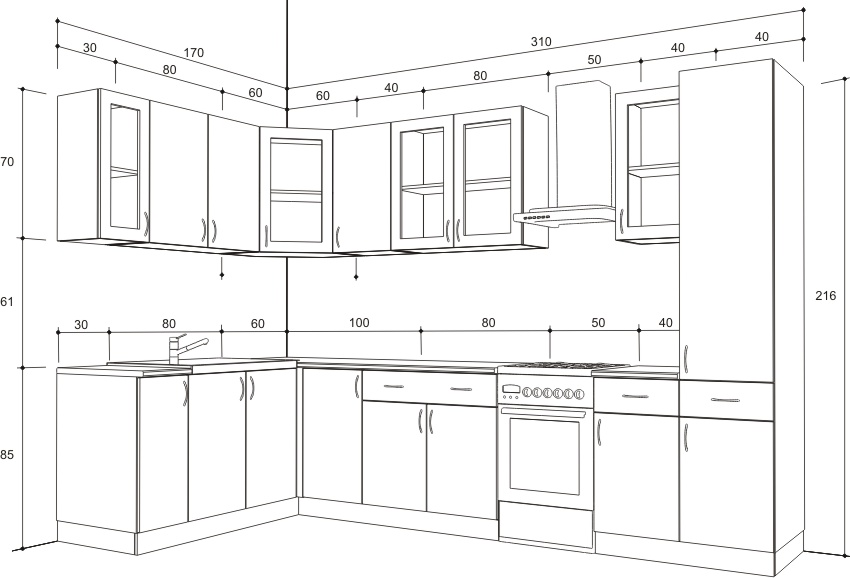

Any sliding wardrobe or other similar design is assembled exclusively after the preliminary creation of a special scheme presented in the form of a drawing. To do this, you should initially decide on the main features of future furniture, for which it is decided:

- what height, width and depth the structure will have;

- what will be the number of different doors, compartments, drawers and other compartments in it;

- what height the mezzanines will have if they are planned in such a cabinet;

- what will be the filling of the cabinet, and it can be represented by numerous partitions, shelves, drawers, rods or other high-quality elements that increase the comfort of use of this product.

After answering these questions, the procedure for creating a sketch of the future cabinet begins. To do this, it must be drawn. If you have experience in creating drawings, then the diagram can be made on a piece of paper. If there are no necessary skills, then it is considered optimal to use special computer programs for design. It is enough to enter predefined data into them, after which the necessary drawing will be automatically received. It is on the basis of it that you can independently assemble the cabinet yourself.

Due to a well-made drawing, you can get an answer to many questions regarding the future cabinet:

- detailing is made;

- the required amount of materials is calculated;

- it is determined what sizes furniture panels should have for designed to create an interior item;

- decides how they will be cut.

Often, a new cabinet is created to replace the old design, and in this case, you can make exactly the same product. After creating the scheme, it is recommended to carefully consider it, since it will be possible to understand on its basis what kind of appearance the future interior item will have. It is advisable to make changes in advance, since during the direct creation of the structure it will be impossible to implement this.

Cabinet Assembly Technology

After all the preparatory steps, you can proceed to the direct creation of the cabinet. You will assemble the construction quite simply if you follow a certain sequence of correct actions.The entire assembly process of the cabinet is divided into several stages, each of which has its own characteristics.

Assembly

If the work is performed for the first time, it is recommended to start with the procedure for creating a standard double-wing cabinet equipped with a small number of internal elements. It does not have any specific elements, so you do not need to spend a lot of time or effort on its creation.

For the formation of the structure, certain elements are certainly cut out, and for this it is recommended to use an electric jigsaw, which provides really smooth and high-quality parts. This tool creates structural elements:

- 2 walls, which are the side parts of the future cabinet;

- the bottom, and it should be high-strength if it is supposed to store shoes in the bottom in such furniture or other elements and structures that have significant weight;

- the lid, and it should not be too heavy, and it is also recommended that it be slightly larger than the width and length of the cabinet, as this provides an attractive cabinet;

- basement, providing closing of the hole formed between the bottom of the cabinet and the floor of the room;

- two doors;

- the back wall, and for it furniture panels or standard thin plywood can be used;

- shelves, and their number should be determined in advance when creating the scheme of the future cabinet.

It is advisable to make grooves under the baseboard at the bottom of the sides of the structure, moreover, they can be rounded or rectangular, and thanks to such elements, it is possible to move the furniture close to the wall of the room.

Before direct assembly of the cabinet, it is recommended to cover all the elements with a special varnish designed for working with wood. It is advisable to apply this tool 2 times to ensure a truly high-quality and reliable coating. After applying the first layer, the surfaces of the structure are definitely ground, but the second application can be performed after the cabinet is directly assembled.

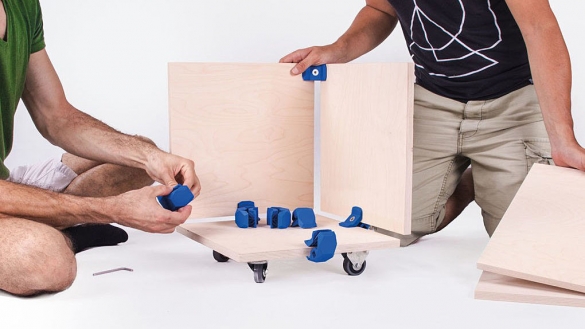

Assembly is a fairly simple job, implemented in sequential actions:

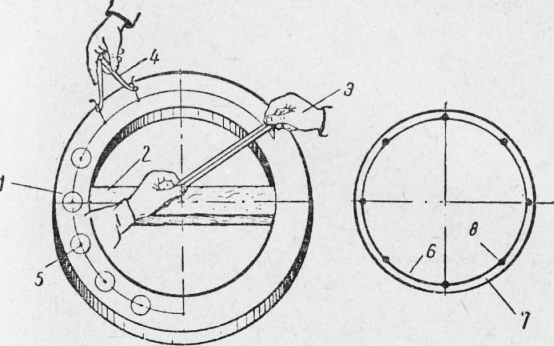

- holes marked for fasteners and future fittings are marked;

- in places where there are marks, holes of the right size are created;

- in the process of work it is taken into account that the hinges are usually fixed at the top and bottom at a distance of 10 cm, however, in the presence of massive doors, it is recommended to use three hinges at all;

- the bottom is fixed between the two side walls with the help of self-tapping screws;

- you can immediately fix the base, for which self-tapping screws are also used;

- a lid is installed at the top, and it is advisable to use a level or other measuring equipment during operation to prevent any distortions or other shortcomings;

- if there are no problems with evenness, then the rear wall is securely fixed, for which small nails are usually used, since this wall has a small mass;

- the door installation process begins, for which bowls of hinges are inserted into pre-made recesses, and the hinges themselves are fixed to the structure with standard self-tapping screws;

- door handles are fastened using conventional screws;

- doors are hung, for which purpose hinges are fixed to the side walls, and it is advisable to use adjustable fasteners, which make it possible to obtain an actually even fastening.

Thus, the assembly procedure of the cabinet is a simple work, easily performed on its own. To do this, only simple sequential actions are performed. In the process, it is necessary to constantly use a level or other similar equipment to quickly see different distortions or other problems, since they must be resolved promptly.

Filling

The assembled design must certainly have different compartments and other elements that ensure ease of its intended use. To do this, you must provide for the presence of boxes, different rods or compartments. Boxes are easily made in successive steps:

- custom plywood is acquired, on which markings are applied in accordance with the required dimensions of the main elements of the future box;

- holes are drilled, and so that the thin material does not break during this process, it is recommended to make holes at a distance of about 10 cm;

- a narrow shield of high attractiveness is used to create the facades of the boxes;

- the received elements are reliably connected to each other;

- for ease of use, it is recommended to install special guides, thanks to which the elements simply slide out and slide back.

In addition to the drawers, there must be a rod in any cabinet. It is intended for hanging various clothes on a coat hanger. For its fixation, special high-strength bar holders are used.

Facade

It is important to get not only a strong and durable cabinet, but also an attractive interior item that fits perfectly into the existing style of the room. Different methods can be used for this. The initially obtained construction is certainly covered with a reliable varnish, which provides a high-quality protective coating. Various methods are used for decoration:

- painting in different shades, for which it is necessary to use special paints designed to work with wood, and it is also taken into account that the resulting color should fit perfectly into the existing color scheme;

- making different threads with your own hands;

- the use of a variety of films;

- hand painting, realized only with the appropriate skills;

- the use of expensive, bright and beautiful accessories that attract attention and provide excellent decoration of the structure.

Thus, if you were going to purchase a wardrobe for any room in a residential building or apartment, then self-creation is considered a great solution. Different materials can be used for this, but the use of standard furniture panels is considered optimal. Designs from them have many advantages. The procedure for creating a cabinet is considered simple if you carefully study the instructions in advance and use only high-quality materials.

Video